Fitting types

Top plate. Bolt hole. Plug-in stem. Threaded pin.

Plate (top plate)

Bolt hole

Steel plug-in stem

Threaded pin

(product code suffix: -GS...)

Plug-in stem

(product code suffix: -ES)

Synthetic caster socket for round tubes (product code: RHR...)

Metal expander

(product code suffix: -E...)

Synthetic expander

(product code suffix: -ER.../-EV...)

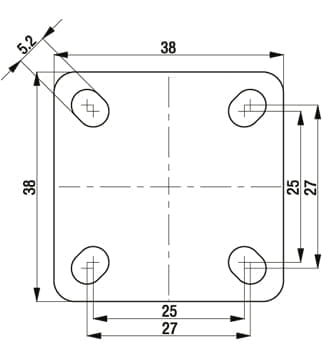

The caster is fixed to a level surface using bolts and

nuts. The bolt hole spaces are standardised.

Plate fittings are available for both swivel and rigid casters and are used for light-duty, transport

equipment and heavy-duty casters.

The plate must be aligned with the short side facing

in the running direction for casters with a swivel

lock.

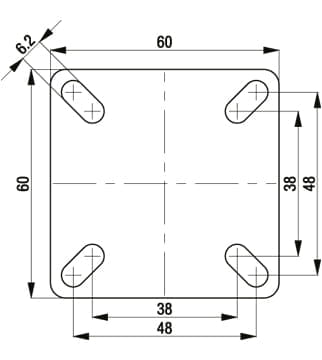

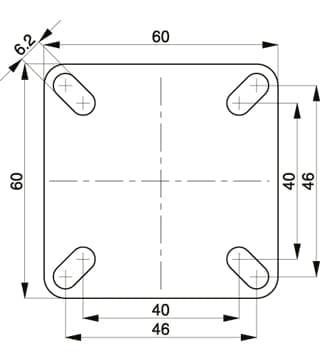

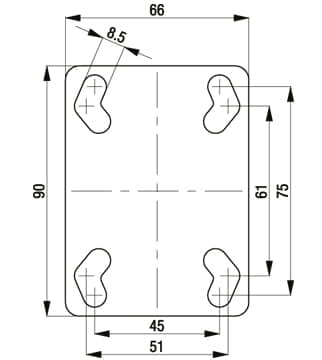

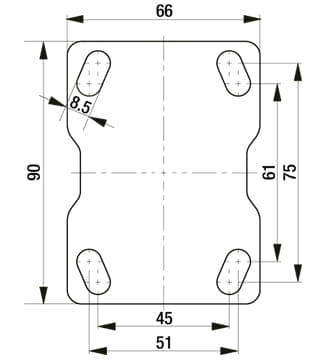

The following dimensions must be taken into

consideration when selecting the plate fitting:

• plate size (external dimensions)

• bolt hole spaces

• bolt hole Ø

The caster is attached using a connection element

(e.g. a bolt) through the central hole of the swivel

head. For levelling casters (series HRIG), the bolt

hole has a female thread and the connection

element is screwed into the central kingpin of the

swivel rig from the unit side.

The load capacities specified here can only be

reached if the top plate lies along the entire

diameter of the swivel caster.

This fitting type does not provide positive anti-twist

locking, and therefore reduces the load capacity of

the swivel head brake.

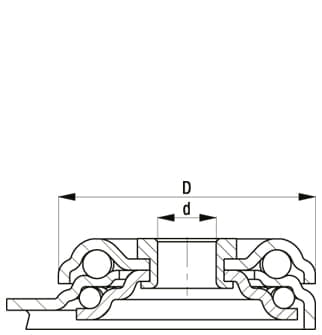

Using a bolt hole to install the caster is a

cost-effective solution, which only requires a single

bolt (ideally in compliance with DIN 912 / ISO 4762).

This fitting type is primarily used for light-duty and

transport equipment casters.

The following dimensions must be taken into

consideration when selecting the fitting with a bolt

hole:

• plate Ø (external dimensions) (D)

• bolt hole Ø (d)

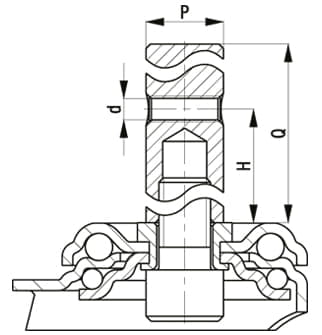

The caster is fitted using a plug-in stem, which is

inserted into a corresponding tube or hole and

secured. The stem fitting is fixed to the caster and a

fixing bolt (cross hole) or clamp must be used to

prevent it rotating or falling out.

The hole must be aligned transverse to the running

direction for casters with a swivel lock.

The load capacities specified here can only be

reached if the top plate lies along the entire

diameter of the swivel caster.

Stem fittings are primarily used for light-duty,

synthetic and transport equipment casters.

A stainless steel plug-in stem fitting is available for

stainless steel swivel casters.

The following dimensions must be taken into

consideration when selecting the fitting with a stem:

• stem Ø (P)

• stem length (Q)

• position of the cross hole (H), if applicable

• diameter of the cross hole (d), if applicable

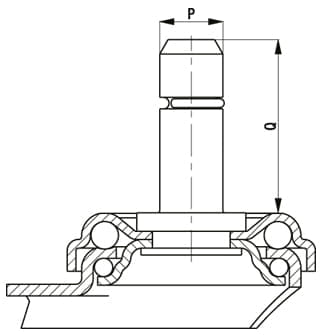

The caster is fitted using a threaded pin, which is

bolted to the transport equipment using a female

thread or a cylindrical hole and nut.

Threaded pin fittings are primarily used for

light-duty casters.

A stainless steel threaded pin (-GSX...) is available

for corrosion-resistant synthetic swivel casters.

The following dimensions must be taken into

consideration when selecting the fixing with a

threaded pin:

• threaded pin Ø (thread M10 or M12) (P)

• threaded pin length (protrusion over the caster)

(Q)

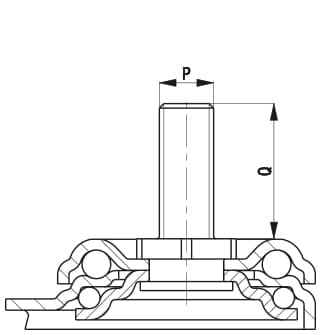

The caster is fitted using a plug-in stem, which is

inserted into a corresponding tube or hole using a

synthetic caster socket. The pin is firmly connected

with the caster. A spring washer ensures that the

swivel caster cannot fall out.

Because this fitting type does not provide an

anti-twist lock, a swivel head brake will have no

effect.

A plug-in stem is a quick and cost-effective method

for fitting the caster to the unit. Plug-in stem fittings

are primarily used for light-duty casters.

The following dimensions must be taken into

consideration when selecting the fitting with a

plug-in stem:

• pin Ø (P)

• pin length (Q)

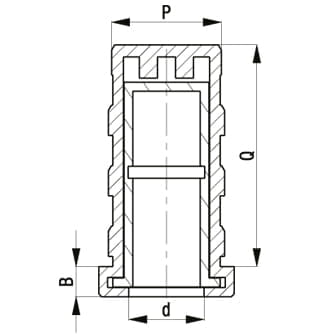

A synthetic caster socket is an adapter that is used

to reduce the internal diameter of tubes to the

diameter of the plug-in stem. The synthetic caster

socket is pressed or driven into the holder on the

unit (round tube). A swivel caster with a plug-in stem is then inserted into the caster socket.

The following dimensions must be considered when

selecting a synthetic caster socket:

• internal tube Ø (P)

• pin Ø (d)

• fitting length (Q)

• flange length (B)

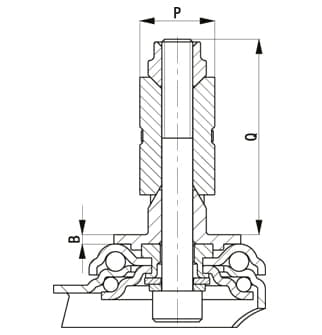

The caster is fitted using a metal expander that is

inserted into a hole or a square/round tube.

The bolt spreads the clamping wedge and presses it

against the inner tube wall.

The tightening torque should not exceed 50 Nm. The

tightening torque can be reduced to 16 Nm for

low-strength thin tubes. A hexagon on the bottom

side of the expander prevents the fitting from

rotating relative to the caster and coming undone.

Metal expander fittings are used for light-duty and

synthetic casters.

The following dimensions must be considered when

selecting an expander fitting:

• internal tube dimension (P)

• tube shape (round or square tube)

• fitting length (Q)

• flange length (B)

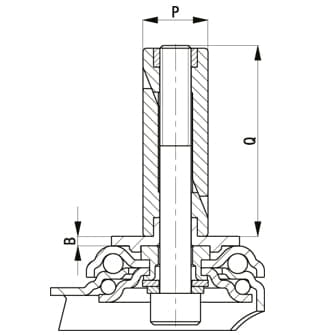

The caster is fitted using a synthetic expander,

which is inserted into a hole or a square/round tube.

The bolt presses the synthetic clamping wedge

against the inner tube wall.

A synthetic expander provides greater protection for

the inside of the tube compared to metal expander

fittings. However, it provides less holding force than

a metal expander fitting. A hexagon on the bottom

side of the expander prevents the fitting from

rotating relative to the caster and coming undone.

Synthetic expander fittings are mainly used for

light-duty and synthetic casters. A synthetic expander with a corrosion-resistant

clamping screw (-EXR.../-EXV...) is also available.

To the product video

The following dimensions must be considered when

selecting an expander fitting:

• internal tube dimension (P)

• tube shape (round or square tube)

• fitting length (Q)

• flange length (B)

Plate fitting

Top plate fittings for light-duty and synthetic casters

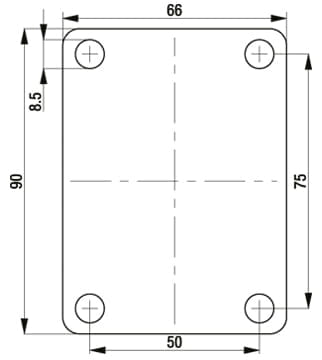

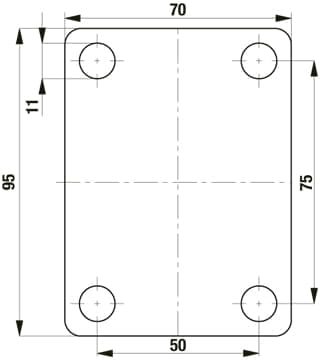

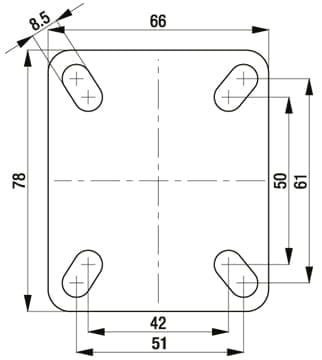

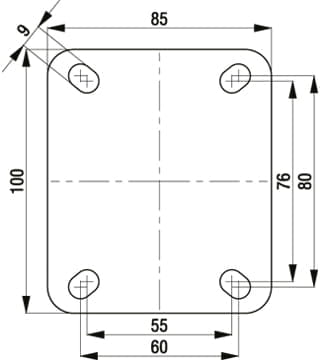

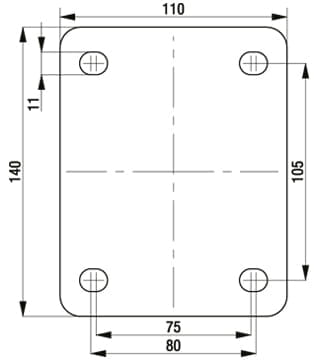

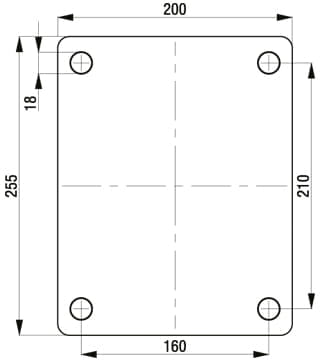

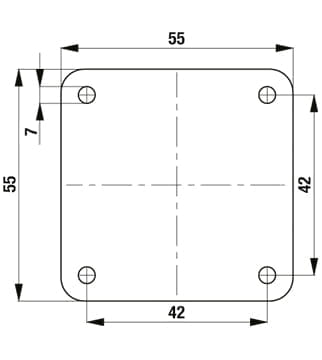

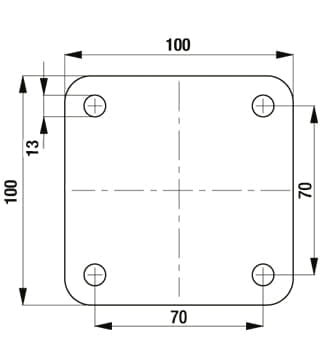

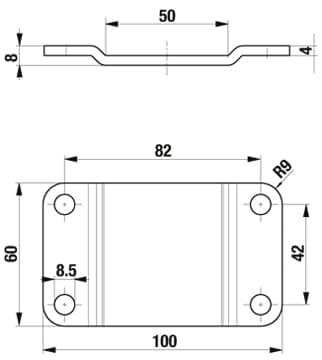

Plate no. 20

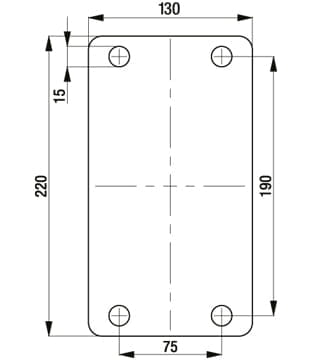

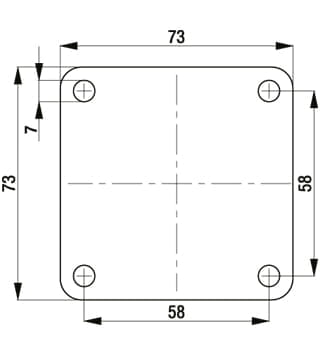

Plate no. 22

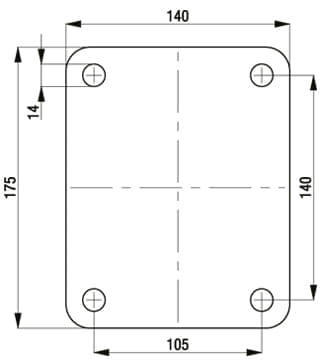

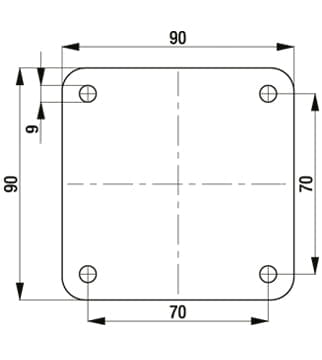

Plate no. 23

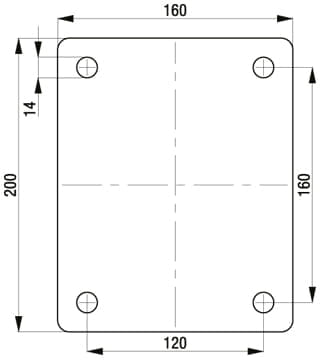

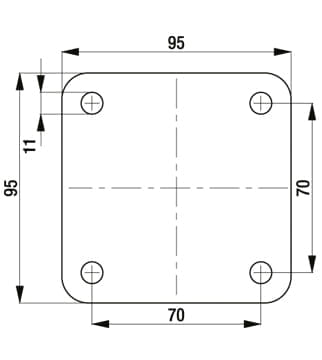

Plate no. 25 (swivel caster)

Plate no. 25 (rigid caster)

Plate no. 26

Plate no. 27

Plate no. 28

Use in rig series:

LKDB wheel Ø50–75 mm

Use in rig series:

LPA / BPA wheel Ø 35–100 mm

LPXA / BPXA Rad-Ø 50–75 mm

LDA wheel Ø 50 mm

Use in rig series:

LDA wheel Ø 75 mm

LKDG / LKDB wheel Ø 75–100 mm

Use in rig series:

LKPA wheel Ø 80–150 mm

LKPXA wheel Ø 80–125 mm

LWK / LWG-P25 wheel Ø 100–125 mm

LWKX / LWGX-PX25 wheel Ø 100–125 mm

LKFG / BKFG wheel Ø 125 mm

Use in rig series:

BKPA wheel Ø 80–150 mm

BKPXA wheel Ø 80–125 mm

Use in rig series:

LKPXA / BKPXA wheel Ø 125 mm

LWKX / LWGX-PX26 wheel Ø 125 mm

Use in rig series:

LKFGX / BKFGX wheel Ø 125 mm

Use in rig series:

LWK / LWG-P28 wheel Ø 100–125 mm

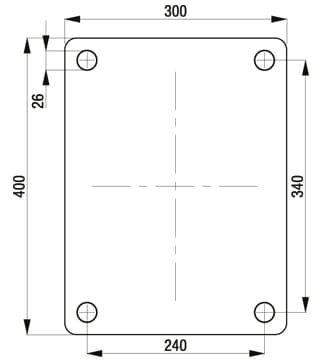

Top plate fittings for transport equipment and heavy-duty casters

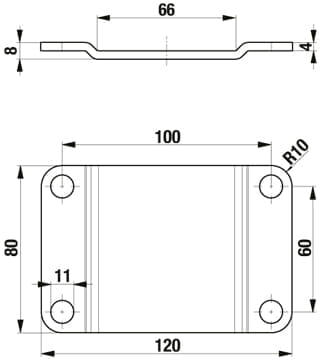

Plate no. 1

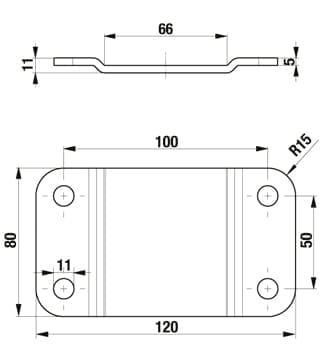

Plate no. 3

Plate no. 7

Plate no. 9

Use in rig series:

LE / B wheel Ø 60–125 mm

LEX / BX wheel Ø 75–200 mm

L / B wheel Ø 75–125 mm

LX / BX wheel Ø 100–125 mm

LI / B wheel Ø 80–125 mm

LIX / BX wheel Ø 80–125 mm

LK / BK wheel Ø 75–125 mm

LKX / BKX wheel Ø 75–125 mm

LIK / BIK wheel Ø 100–125 mm

LIKX / BKX wheel Ø 100–125 mm

LH / BH wheel Ø 75–125 mm

LHD wheel Ø 60–80 mm

LHF / BHF wheel Ø 100–125 mm

LPFE / BPFE wheel Ø 100–125 mm

HRLH / HRLHD wheel Ø 75 mm

HRLK wheel Ø 75–100 mm

Use in rig series:

LE / B wheel Ø 150–200 mm

LEX / BX wheel Ø 150–200 mm

L / B wheel Ø 140–250 mm

LX / BX wheel Ø 150–200 mm

LI / BI wheel Ø 150–200 mm

LIX / BX wheel Ø 150–200 mm

LK / BK wheel Ø 100–200 mm

LKX / BKX wheel Ø 125–200 mm

LUH / BH wheel Ø 125–200 mm

LH / BH wheel Ø 100–250 mm

LHD wheel Ø 80–125 mm

LO / BO wheel Ø 125–300 mm

LOD / BOD wheel Ø 75–125 mm

LS / BS wheel Ø 100–200 mm

LSD / BSD wheel Ø 80–125 mm

LHF / BHF wheel Ø 100–200 mm

LPFE / BPFE wheel Ø 125–150 mm

LSFN / BSFN wheel Ø 160–200 mm

LSFE / BSFE wheel Ø 160–200 mm

LIO / BO wheel Ø 125–2500 mm

Use in rig series:

L wheel Ø 250–280 mm

Use in rig series:

B wheel Ø 250–280 mm

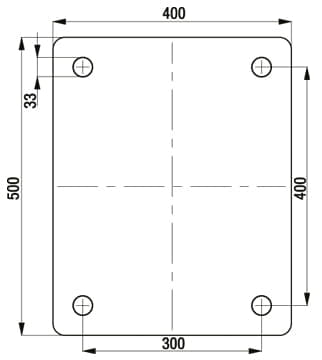

Top plate fittings for heavy-duty casters

Plate no. 35

Plate no. 36

Plate no. 38

Plate no. 39

Plate no. 42

Plate no. 45

Plate no. 48

Use in rig series:

LS / BS wheel Ø 150–400 mm

LSD / BSD wheel Ø 100–200 mm

LSFN / BSFN wheel Ø 200–250 mm

LSFE / BSFE wheel Ø 200–250 mm

HRLSD wheel Ø 125 mm

Use in rig series:

LS / BS wheel Ø 300–520 mm

LSFN / BSFN wheel Ø 250–300 mm

LSFE / BSFE wheel Ø 250 mm

Use in rig series:

LS / BS wheel Ø 200–620 mm

LSD / BSD wheel Ø 125–360 mm

Use in rig series:

BSD wheel Ø 300 mm

Use in rig series:

LS / BS 250–600 mm

LSD / BSD 250–500 mm

Use in rig series:

LSD / BSD wheel Ø 300–400 mm

Use in rig series:

LSSD / BSSD wheel Ø 500 mm

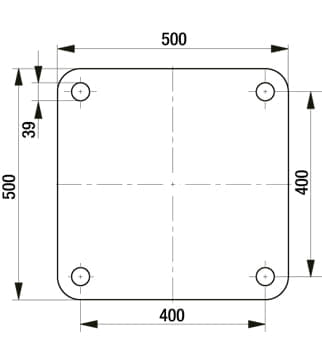

Top plate fittings for levelling casters

Plate no. 71

Plate no. 72

Plate no. 74

Plate no. 76

Plate no. 78

Use in rig series:

HRP wheel Ø 45 mm

Use in rig series:

HRP wheel Ø 50 mm

Use in rig series:

HRP wheel Ø 63 mm

Use in rig series:

HRP wheel Ø 72 mm

HRSP wheel Ø 72 mm

Use in rig series:

HRSP wheel Ø 90 mm

Top plate fittings with imperial dimensions (inches)

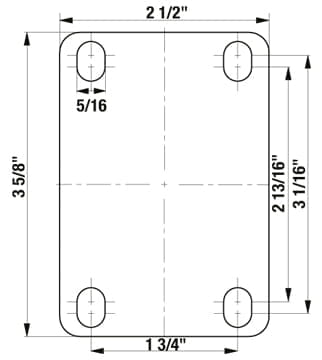

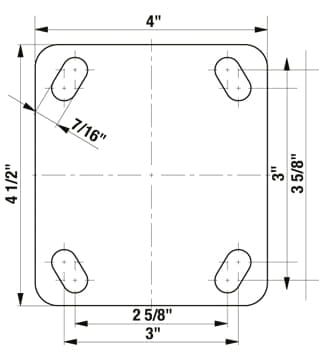

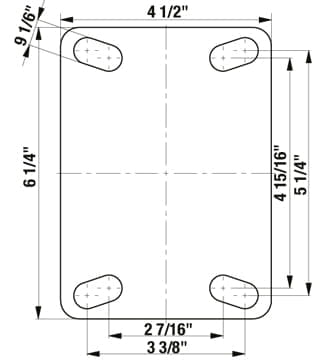

Plate no. 12

Plate no. 14

Plate no. 16

Top plate fittings with non-metric dimensions (inches)

in accordance with ASME B56.11.1

(see Blickle “American Standard Casters” catalog)

Top plate fittings with non-metric dimensions (inches)

in accordance with ASME B56.11.1

(see Blickle “American Standard Casters” catalog)

Top plate fittings with non-metric dimensions (inches)

in accordance with ASME B56.11.1

(see Blickle “American Standard Casters” catalog)

Top plate fittings for Progressus casters

Plate no. PG1

Plate no. PG2

Plate no. PG3

Use in rig series:

LPX / BPX wheel Ø 84–105 mm

Use in rig series:

LPX / BPX wheel Ø 120–150 mm

Use in rig series:

LPX / BPX wheel Ø 186 mm