Blickle wheel series info box

Tread and tire hardness. Smooth operation and floor preservation.

To make it easier for you to choose the correct product, we provide a Blickle info box for each wheel series. This provides an overview of the tread and tire hardness of a wheel, its smooth operation and floor preservation, rolling resistance and wear resistance.

Tread and tire hardness is rated on a scale from very soft to very hard, while the other categories are rated from satisfactory to outstanding.

| Tread and tire hardness | |

|

65 Shore A |

| Smooth operation and floor preservation | |

|

excellent |

| Rolling resistance | |

|

very good |

| Wear resistance | |

|

good |

Tread and tire hardness

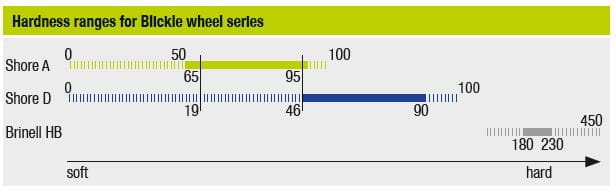

The tread & tire hardness is indicated in the info box in images on the product pages. The further the marking is to the right, the harder the tread. Hardness for

- elastomers and polyurethanes is provided in Shore A,

- Shore D for solid plastics and

- using the Brinell scale for metals.

There is no linear correlation between the various hardness testing methods. The values in the graphic were determined empirically and are provided for reference purposes.

| Material | Tread and tire hardness | ||

| Pneumatic tire / soft rubber |  |

50-60 Shore A | |

| Elastic solid rubber |  |

65 Shore A | |

| Super-elastic solid rubber |  |

70 Shore A | |

| Standard solid rubber |  |

80 Shore A | |

| Thermoplastic polyurethane (TPU), soft |  |

80 Shore A | |

| Thermoplastic rubber-elastomer (TPE) |  |

85 Shore A | |

| Polyurethane 75 Shore A |  |

75 Shore A | |

| Polyurethane 92 Shore A |  |

92 Shore A | |

| Thermoplastic polyurethane (TPU), hard |  |

92–98 Shore A | |

| Polypropylene |  |

60 Shore D | |

| Nylon |  |

70 Shore D | |

| Cast nylon |  |

80 Shore D | |

| Cast iron / steel |  |

180–230 HB |

Smooth operation and floor preservation

The higher the score in this category, the quieter the wheel is and the easier it is on surfaces.

Floor preservation

Hard treads put more strain on a floor than softer

treads. A tread with five points in the smooth

operation and floor preservation category has

exceptionally good floor preservation qualities.

Floor surface preservation is measured on the basis of average floor pressure. Reference values for each tread material are provided to the right.

Smooth operation

In principle, vehicles tend to be quieter when they

have large wheels with soft thick treads. Hard

treads result in higher levels of noise than soft

treads. A high score in the smooth operation and

floor preservation category would therefore lead to

expect low levels of vibration and noise emission

when transporting goods.

Hard wheels can also be used with low levels of noise and a high degree of operational comfort when transporting light loads on a soft surface (e.g. carpet).

Calculating average floor pressure

The average floor pressure is calculated by

dividing the radial force [N] by the wheel contact

surface [mm²].

| Material | Smooth operation / floor preservation | Average floor pressure | |

| Pneumatic tire / soft rubber |  |

0,8 N/mm² | |

| Elastic solid rubber |  |

1,8 N/mm² | |

| Super-elastic solid rubber |  |

1,5 N/mm² | |

| Standard solid rubber |  |

3,5 N/mm² | |

| Thermoplastic polyurethane (TPU), soft |  |

4,0 N/mm² | |

| Thermoplastic rubber-elastomer (TPE) |  |

4,5 N/mm² | |

| Polyurethane 75 Shore A |  |

3,5 N/mm² | |

| Polyurethane 92 Shore A |  |

8,0 N/mm² | |

| Thermoplastic polyurethane (TPU), hard |  |

11,0 N/mm² | |

| Polypropylene / nylon |  |

40,0 N/mm² | |

| Cast nylon |  |

60,0 N/mm² | |

| Cast iron / steel |  |

>350 N/mm² |

Starting, rolling and swivel resistance

Starting resistance reflects the amount of force required to get the wheel in motion when it is at a standstill. Rolling resistance refers to the amount of force required to keep the wheel moving in a uniform manner. Starting and rolling resistance are affected by the following factors:

- wheel diameter

- tread geometry

- tread & tire hardness

- rebound resilience of the tread

- wheel bearing

- surface

Rolling resistance occurs as a result of the constant compression and decompression of the tread while the wheel is rolling (hysteresis).

Rolling resistance is measured using a test bench. Measurements are taken under ideal conditions:

- level, smooth, steel surface free of dirt and obstacles

- speed: 4 km/h

- temperature: +20 °C

- load: ⅔ of max. load capacity

These standardised conditions make it possible to compare the rolling resistances of different wheel series.

| Material | Rolling resistance | ||

| Pneumatic tire / soft rubber |  |

good | |

| Elastic solid rubber |  |

very good | |

| Super-elastic solid rubber |  |

good | |

| Standard solid rubber |  |

satisfactory | |

| Thermoplastic polyurethane (TPU), soft |  |

very good | |

| Thermoplastic rubber-elastomer (TPE) |  |

very good | |

| Polyurethane 75 Shore A (Softhane®) |  |

very good | |

| Polyurethane 75 Shore A (Besthane® Soft) |  |

excellent | |

| Polyurethane 92 Shore A (Extrathane®) |  |

very good | |

| Polyurethane 92 Shore A (Besthane®) |  |

excellent | |

| Thermoplastic polyurethane (TPU), hard |  |

very good | |

| Polypropylene / nylon |  |

excellent | |

| Cast nylon |  |

excellent | |

| Cast iron / steel |  |

excellent |

Different application conditions (surface quality, temperature, speed, etc.) must be taken into consideration when designing the running gear and can have a significant impact on rolling resistance.

Swivel resistance is the resistance required to align swivel casters in the direction of travel.

Swivel resistance is affected by the following factors:

- Contact area of the wheel: The contact area of the wheel rotates around its center when the swivel caster turns. This causes friction. The resistance is dependent on the interaction between the surface and the wheel tread, in addition to the size of the contact area.

- Resistance of the swivel head: The structure and quality of the swivel head have an impact on its swivel resistance.

- Offset of the swivel caster: The swivel resistance of the swivel caster is influenced by the distance between the center of the swivel head and the center of the contact area.

Wear resistance

The higher the point score in this category, the greater the wear resistance of the wheel.

In addition to other factors, the wear resistance incorporates the resistance to abrasion of elastomers or thermoplastic elastomers in accordance with ISO 4649. The resistance of other tread materials to abrasion was tested in accordance with ISO 4649.

Tread materials are assigned to different abrasion resistance categories in the graphic to the right.

| Material | Wear resistance | ||

| Pneumatic tire / soft rubber |  |

satisfactory | |

| Elastic solid rubber |  |

good | |

| Super-elastic solid rubber |  |

good | |

| Standard solid rubber |  |

adequate | |

| Thermoplastic polyurethane (TPU), soft |  |

good | |

| Thermoplastic rubber-elastomer (TPE) |  |

satisfactory | |

| Polyurethane 75 Shore A |  |

very good | |

| Polyurethane 92 Shore A |  |

excellent | |

| Thermoplastic polyurethane (TPU), hard |  |

very good | |

| Polypropylene |  |

satisfactory | |

| Nylon |  |

good | |

| Cast nylon |  |

very good | |

| Cast iron / steel |  |

excellent |